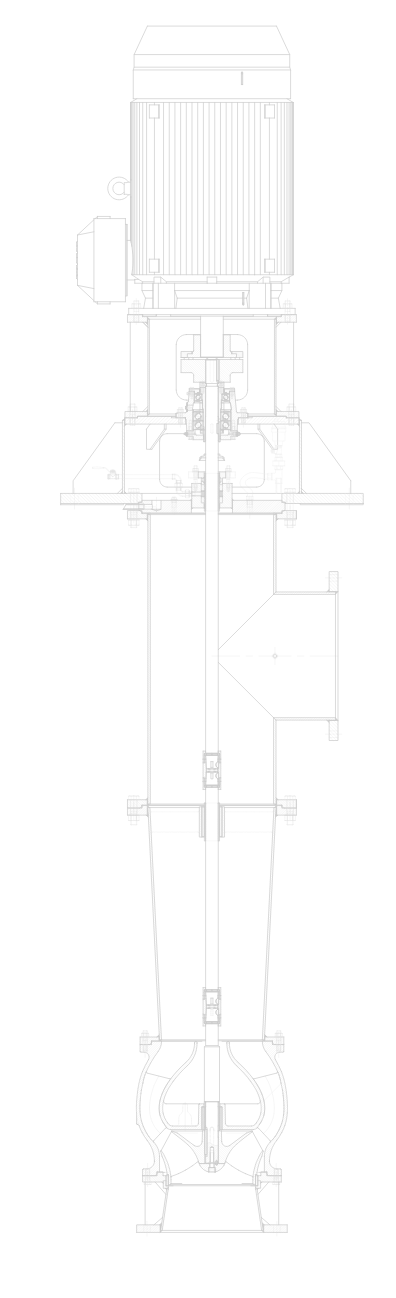

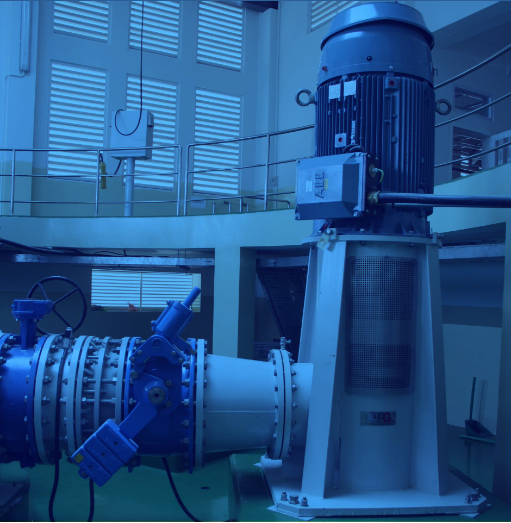

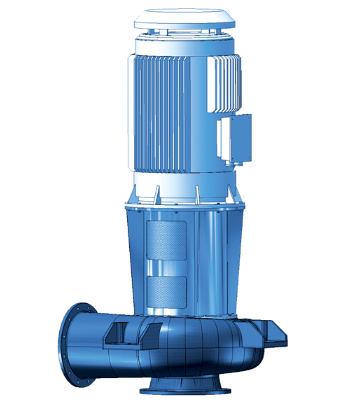

Vertical line shaft pump

In terms of operational safety, the vertical line shaft pump technology offers the dual benefit of having a submersible pump part, directly into the pumped liquid, and another positioned above the surface, for electrical and mechanical driving. These pumps, installed in wells, tanks or through water intakes, allow both dewatering and boosting using a single machine. The high-flow range pumps up to 3m³/second.

Flow: from 30 to 3,000 l/s

Head: up to 400 m

Execution: discharge above or below floor level, assembly with angular gearbox

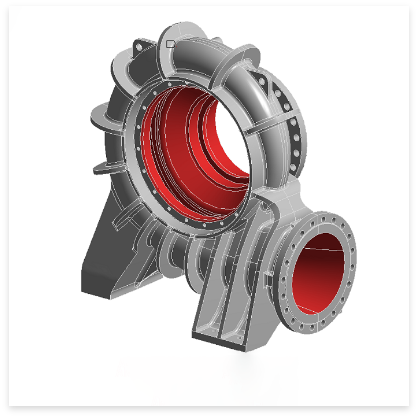

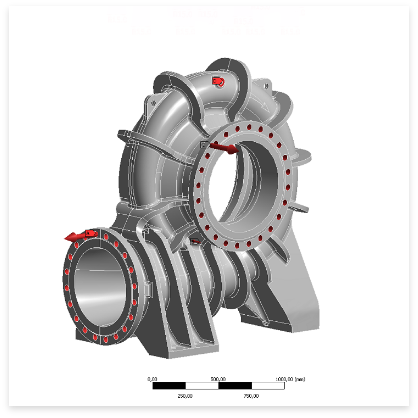

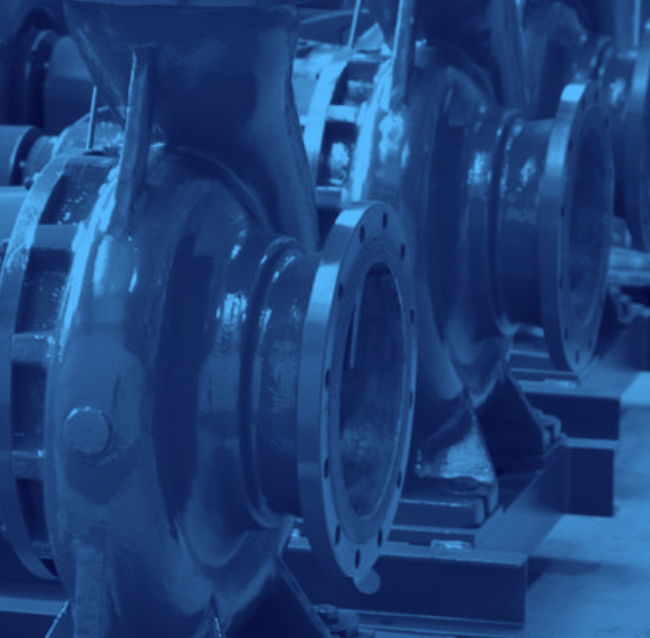

Single-stage pumps

Single-stage pumps are suited to all pumping applications that do not require a high pressure. Their flow range extends from 100 to 3,000 l/s with delivery heads between 20 and 120 m, according to the model. The range is available for mounting, whether horizontal, vertical monobloc or vertical with a cardan shaft.

Flow: from 100 to 3,000 l/s

Head: from 10 to 120 m

Execution: horizontal, vertical, vertical with a cardan shaft

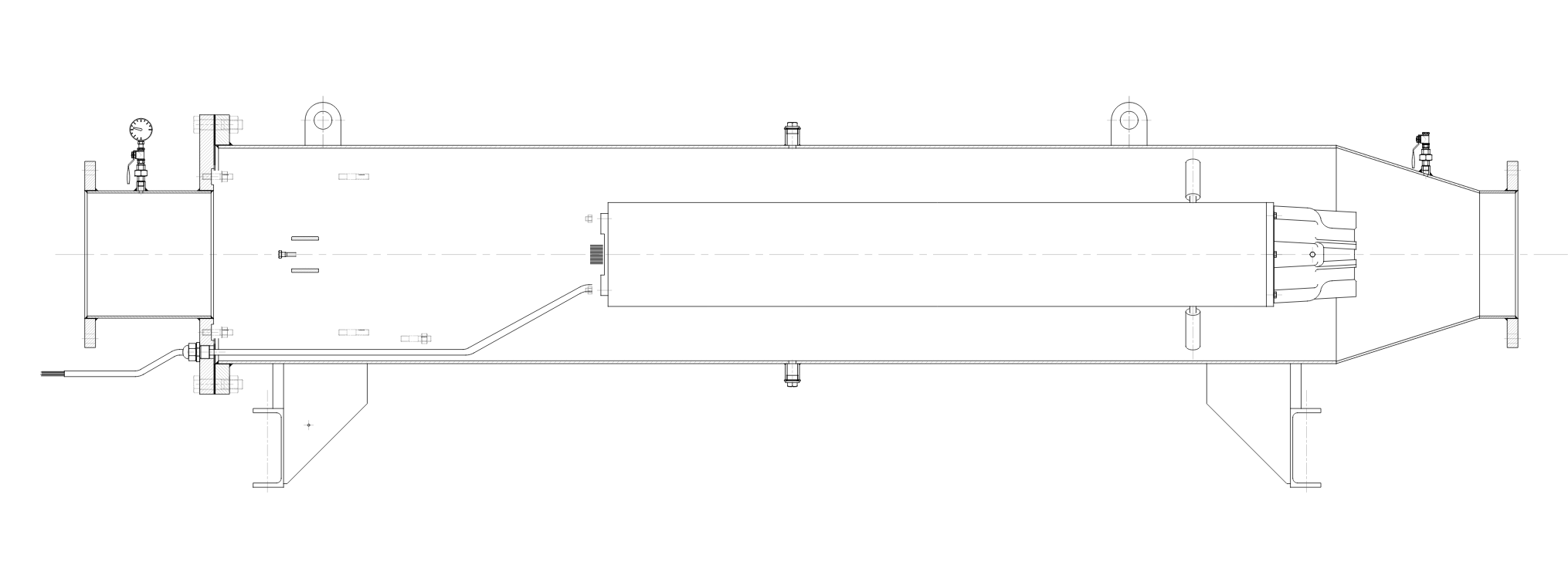

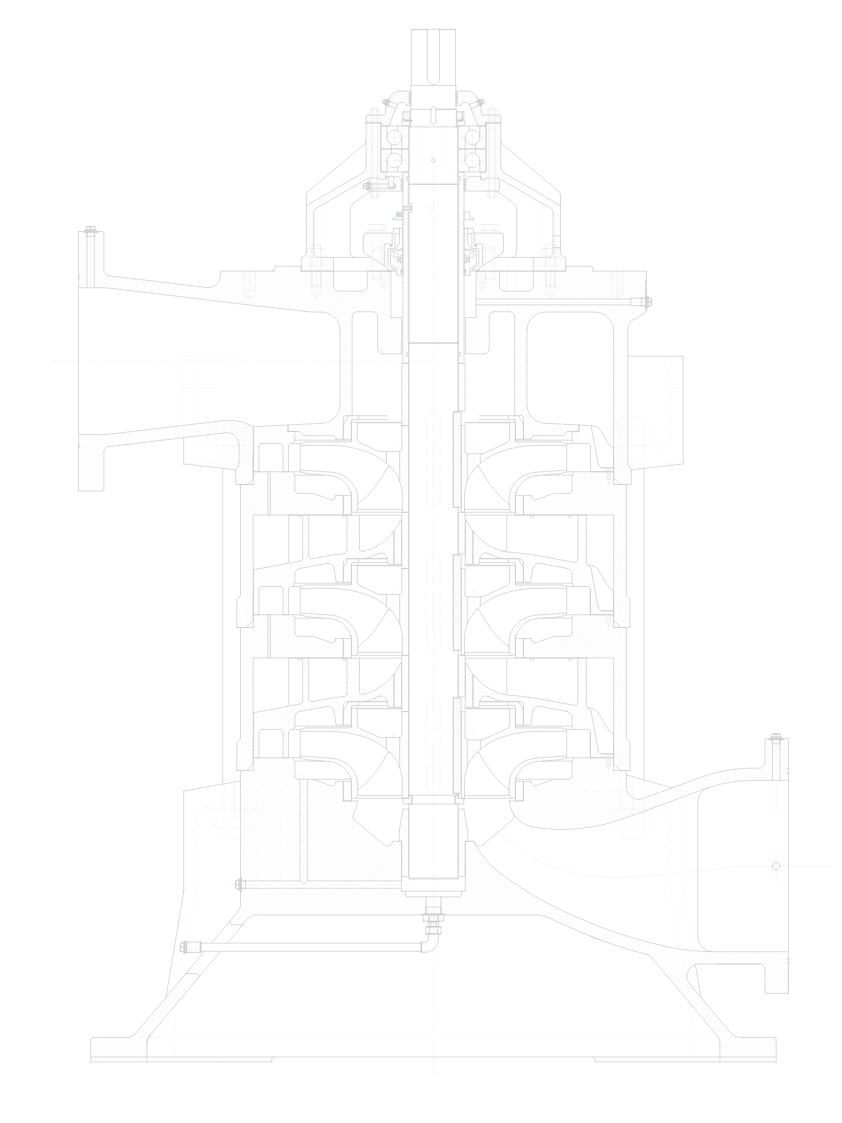

Multistage pumps

Surface multistage pumps with double-bearing technology are recommended to pump clear or slightly raw untreated water, which requires high pressure. The M series multistage pumps can be mounted horizontally or vertically, depending on installation constraints. The vertical alternative driven by cardan shaft is also available.

Flow: 30 to 500 l/s

Head: up to 400 m

Execution: horizontal, vertical, vertical with a cardan shaft

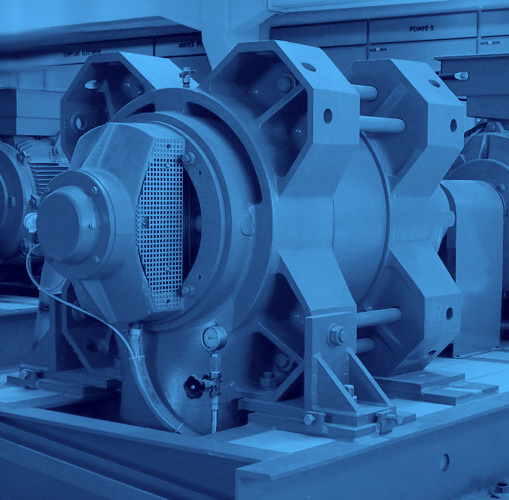

Submersible pumps

Submersible pumps are designed for pumping operations when the whole of the machine (pumps and electric motor) are fully immersed. This solution allows pumping through borehole, water intake and tanks with neither suction condition constraints nor heavy civil works. The 4- and 6-pole submersible pumps (1,500 and 1,000 rpm) are especially suitable for high-flow secure pumping operations. The flow range extends from 30 to 500 l/s with delivery heads between 20 and 250 m.

Flow: from 30 to 500 l/s

Head: up to 250 m

Execution: horizontal, vertical, and booster